Multi Level Protection Program

Protect your crane

Amco Veba’s MLP Program ensures all electrical and structural components, includin crane carpentry, hydraulic cylinder ros, fittings, hoses and piping, pins, hydraulic fittings, bolts, juntion boxes are able to meet the rigorous demands of our customer’s marine applications.

Because we understand the cost impact of service and downtime, all parts have been designed and selected for easy ease of maintenance and each crane component selected and designed for long life.

AMCO VEBA’S MARINE MLP PROGRAM encourages our customers to work with our field representatives and enigneers.

In selecting the most suitable crane protection level for the environment in which the crane will operated.

From the softer ambient conditions till the most severe and harsh humid salt ambient.

Want to know more? Contact us today!

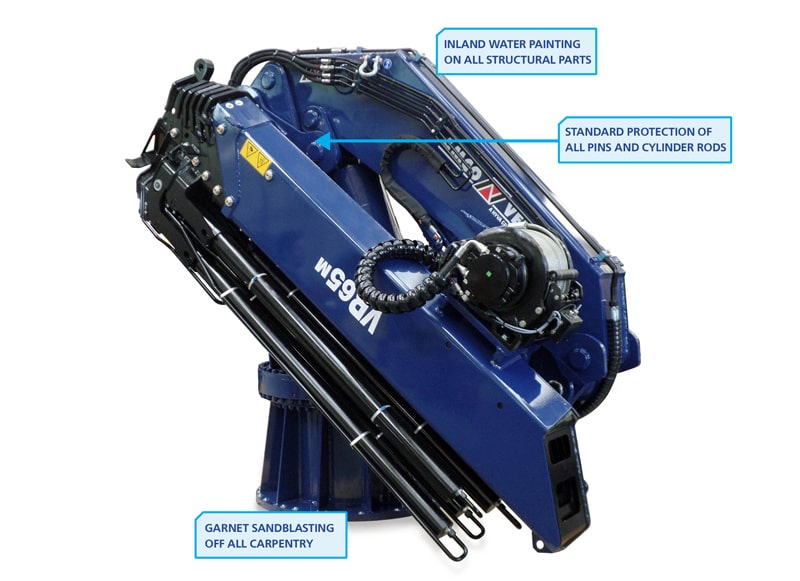

L0 Level

L1 Level

L2 Level

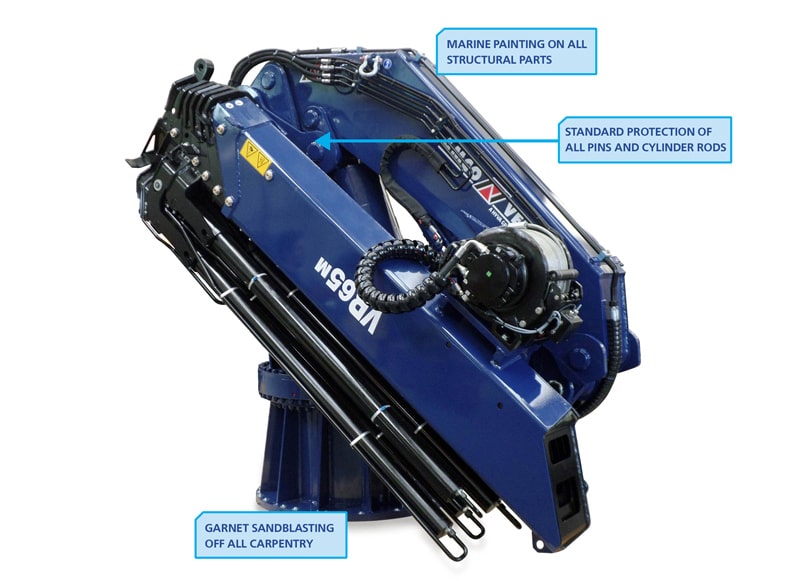

L3 Level

Thermal Metal Spray Process

Thermal Metal Spray Process

Basic protection level

Mostly for Inland application. Perfect for INLAND WATERS installations or boats sailing solely on internal channels, rivers and lakes.

> CRANE structure AND HYDRAULIC CYLINDER SHOOTBLASTING

- Crane structure shot blasted: Sa 2 ISO 8501-1 (BS 4232)

> CRANE structure painting characteristics

- Standard Basic painting with 2 layers bicomponent polyurethane primer and finishing coat with total average thickness of 120 micron

> Hydraulic Cylinders rod plating and pins treatment

- Single layer chrome plating on cylinder rods with average thickness of 25 micron

- Single layer on Internal part of slewing cylinders with average thickness of 50 micron

- Carbonitriding on articulation pins (Tennifer-QPQ) with average thickness of 15 micron + 0.4 mm nitriding depth

> ANTICORROSION TREATMENT ON FITTINGS, BOLTS, NUTS, OTHER PARTS

- zinc plated treatment for all flexible hoses fittings Fe/Zn 12 IV S with average thickness 12 micron

- zinc plated treatment for all hydraulic fittings

- zinc plated treatment on all bolts, nuts, lock nuts

- Zinc plated treatment on telescopic arm register (sliding pads register screws are in bronze and zinc treated steel avoid the galvanic effect and avoid corrosion)

Heavy duty basic protection level

Suitable for MORE SEVERE INLAND APPLICATIONS. Grants a longer lifetime and can be used in more severe applications but always in environment without high water salinity, mainly on river, lakes and inland waters.

> CRANE structure AND HYDRAULIC CYLINDER SHOOTBLASTING

- Crane structure shot blasted: Sa 2 ISO 8501-1 (BS 4232)

> CRANE structure painting characteristics

Heavy Duty Basic painting

- 1st layer epoxy zinc primer applied with parts disassembled average thickness 75 micron

- 2nd layer bicomponent epoxy primer applied with parts disassembled average thickness 180 micron

- 3rd layer bicomponent polyurethane finishing coat average thickness 80 micron

> Hydraulic Cylinders rod plating and pins treatment

- Single layer chrome plating on cylinder rods with average thickness of 25 micron

- Single layer on Internal part of slewing cylinders with average thickness of 50 micron

- Carbonitriding on articulation pins (Tennifer-QPQ) with average thickness of 15 micron + 0.4 mm nitriding depth

> ANTICORROSION TREATMENT ON FITTINGS, BOLTS, NUTS, OTHER PARTS

- zinc plated treatment for all flexible hoses fittings Fe/Zn 12 IV S with average thickness 12 micron

- zinc plated treatment for all hydraulic fittings

- zinc plated treatment on all bolts, nuts, lock nuts

- Zinc plated treatment on telescopic arm register (sliding pads register screws are in bronze and zinc treated steel avoid the galvanic effect and avoid corrosion)

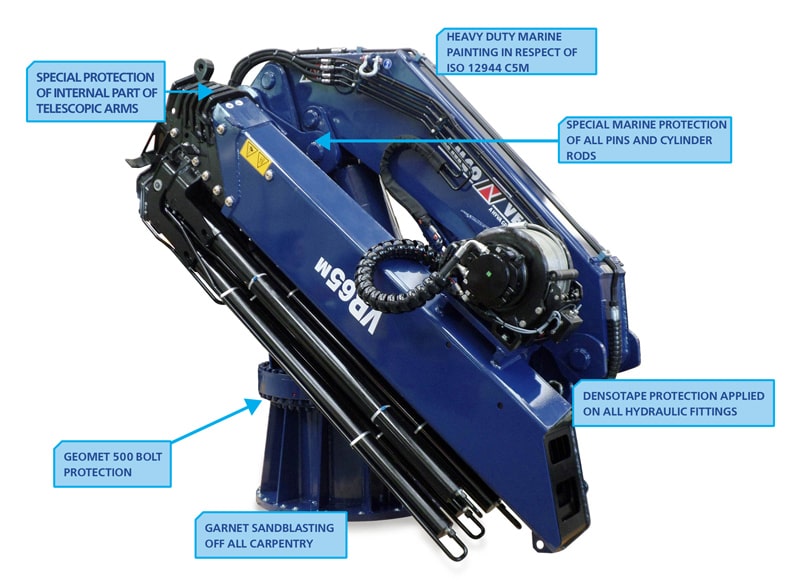

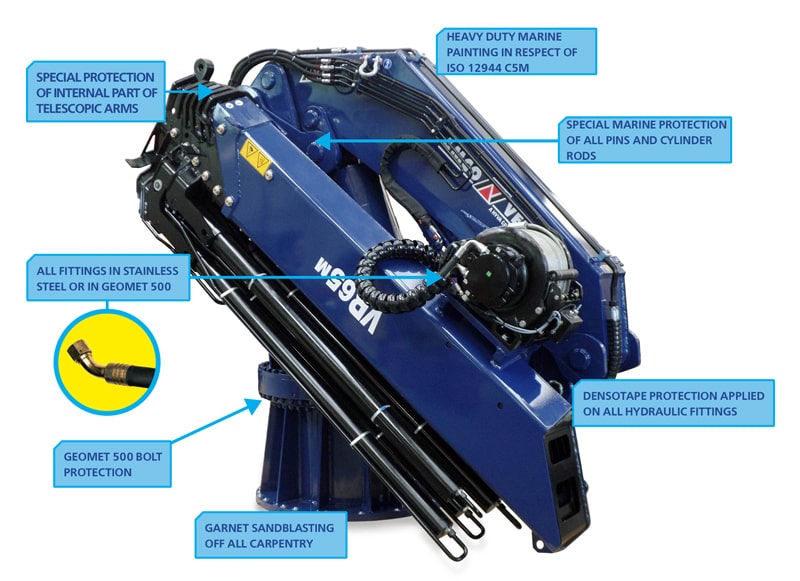

Marine protection level

Suitable for MARINE APPLICATIONS with salt atmosphere and high salinity. The marine protection in respect of ISO12944 C5Mis effective on al structural parts and all crane components granting 5-15 years corrosion resistance in fix port installation or installed on boat sailing on sea.

> CRANE structure AND HYDRAULIC CYLINDER SHOOTBLASTING

- Crane structure shot blasted: Sa 2 ISO 8501-1 (BS 4232)

- All hydraulic cylinders and Rack& Pinion hydraulic Cylinders shot blasted: Sa 2 ISO 8501-1 (BS 4232)

> CRANE structure painting characteristics

Heavy Duty Marine painting in respect of ISO 12944 C5M level for offshore installation (5-15 years lifetime)

- Rack & Pinion Rotation Hydraulic cylinders Flame metalized

- 1st layer epoxy zinc primer applied with parts disassembled average thickness 75 micron

- 2nd layer bicomponent epoxy primer applied with parts disassembled average thickness 180 micron

- 3rd layer bicomponent polyurethane finishing coat average thickness 80 micron

- Telescopic arms with special black RAL 7005 Hard Cataphoresis treatment with high resistance and hardness for soft low friction sliding of boom arms

- Telescopic arms treated INTERNALLY with Cataphoresis ( unique solution on the market ) and sprayed with DINITROL 777 for high corrosion protection

> Hydraulic Cylinders rod plating and pins treatment

- Marine chrome plating Nikrom 500 Nickel + chrome double crossed plating on cylinder rods with average thickness 50 micron

- Hard chrome double crossed plating on cylinder rods (when tubular shape) with average thickness 50 micron

- Carbonitriding on articulation pins (Tennifer-QPQ) with average thickness of 15 micron + 0.4 mm nitriding depth

- Special treatment with DINITROL 777 on all internal diameter of pins and all external pin surfaces

> ANTICORROSION TREATMENT ON FITTINGS, BOLTS, NUTS, OTHER PARTS

- Zinc plated treatment for all flexible hoses fittings Fe/Zn 12 IV S with average thickness 12 micron

- Geomet treatment on all hydraulic fittings

- Geomet treatment on all bolts , nuts ,lock nuts

- Stainless steel nuts on telescopic arm register (sliding pads register screws are in bronze and stainless steel avoid the galvanic effect and avoid corrosion)

- Denso tape applied on all hydraulic connections to protect form corrosion

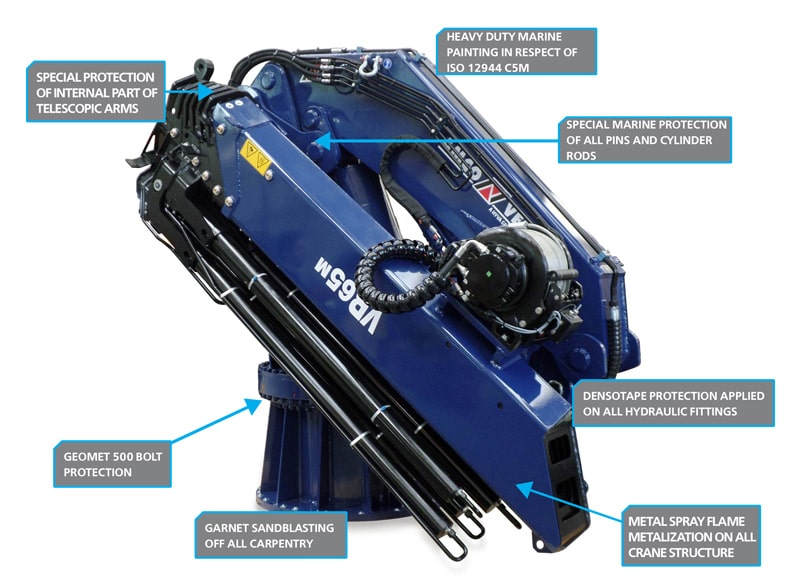

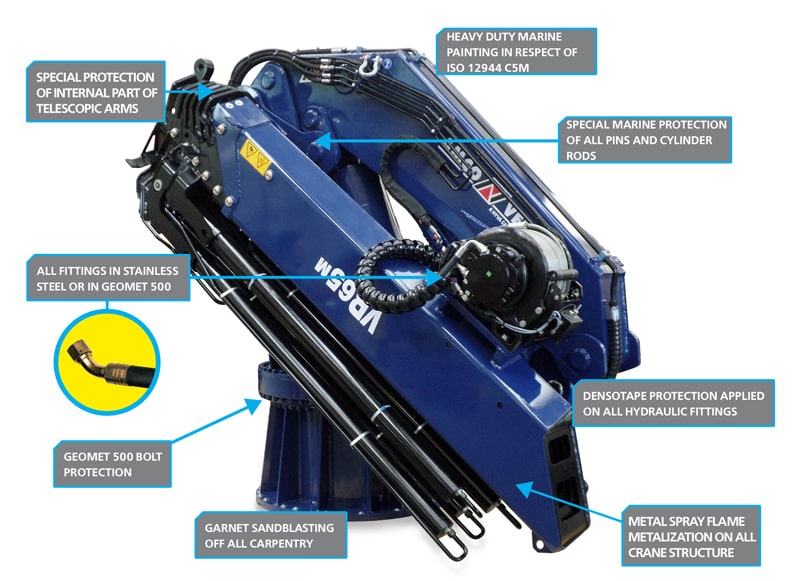

Heavy duty marine protection level

Suitable for HEAVY DUTY MARINE APPLICATION with presence of high humidity and high salinity and very harsh marine conditions. To be adopted for the higher severe marine applications on offshore vessel, boats and offshore platform.

> CRANE structure AND HYDRAULIC CYLINDER SHOOTBLASTING

- Crane structure shot blasted: Sa 2 ISO 8501-1 (BS 4232)

- All hydraulic cylinders and Rack& Pinion hydraulic Cylinders shot blasted: Sa 2 ISO 8501-1 (BS 4232)

> CRANE structure painting characteristics

Heavy Duty Marine painting in respect of ISO 12944 C5M level for offshore installation (5-15 years lifetime)

- Rack & Pinion Rotation Hydraulic cylinders Flame metalized

- 1st layer epoxy zinc primer applied with parts disassembled average thickness 75 micron

- 2nd layer bicomponent epoxy primer applied with parts disassembled average thickness 180 micron

- 3rd layer bicomponent polyurethane finishing coat average thickness 80 micron

- Telescopic arms with special black RAL 7005 Hard Cataphoresis treatment with high resistance and hardness for soft low friction sliding of boom arms

- Telescopic arms treated INTERNALLY with Cataphoresis ( unique solution on the market ) and sprayed with DINITROL 777 for high corrosion protection

> Hydraulic Cylinders rod plating and pins treatment

- Marine chrome plating Nikrom 500 Nickel + chrome double crossed plating on cylinder rods with average thickness 50 micron

- Hard chrome double crossed plating on cylinder rods (when tubular shape) with average thickness 50 micron

- Carbonitriding on articulation pins (Tennifer-QPQ) with average thickness of 15 micron + 0.4 mm nitriding depth

- Special treatment with DINITROL 777 on all internal diameter of pins and all external pin surfaces

> ANTICORROSION TREATMENT ON FITTINGS, BOLTS, NUTS, OTHER PARTS

- Geomet treatment on all hydraulic fittings

- Geomet treatment on all bolts , nuts ,lock nuts

- Stainless steel nuts on telescopic arm register (sliding pads register screws are in bronze and stainless steel avoid the galvanic effect and avoid corrosion)

- Denso tape applied on all hydraulic connections to protect form corrosion

> STAINLESS STEEL FITTINGS, BOLTS, NUTS, OTHER PARTS

- Stainless steel A4 for all fittings fitted on rubber hoses

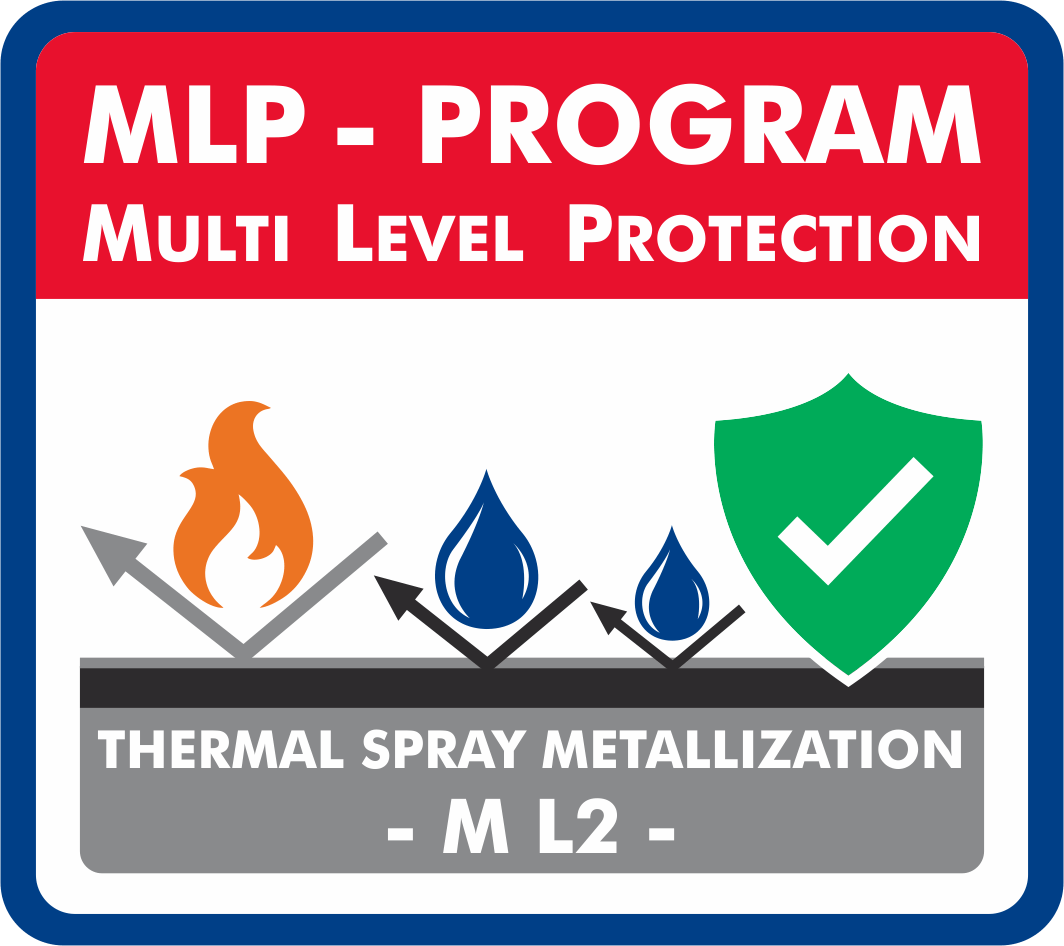

Thermal Metal Spray Process

Additional protection process available on ML2 and ML3.

Thermal Metal spraying is a surface coating process where a liquid metal alloy (zinc/aluminium) is sprayed onto the surface of the crane carpentry.

It provides the higher level of corrosion protection to ferrous metals and improve wear resistance in respect of ISO 12944 CX level granting more of 15 years lifetime.

This treatment includes:

- Thermally sprayed coatings of zinc and zinc alloys

- 120 micron zinc layer

- Primer for filling up holes

- Up to 144 months of resistance in CX exposure conditions, according to ISO 12944

Thermal Metal Spray Process

Additional protection process available on ML2 and ML3.

Thermal Metal spraying is a surface coating process where a liquid metal alloy (zinc/aluminium) is sprayed onto the surface of the crane carpentry.

It provides the higher level of corrosion protection to ferrous metals and improve wear resistance in respect of ISO 12944 CX level granting more of 15 years lifetime.

This treatment includes:

- Thermally sprayed coatings of zinc and zinc alloys

- 120 micron zinc layer

- Primer for filling up holes

- Up to 144 months of resistance in CX exposure conditions, according to ISO 12944